iG5A Series

Drive with sensorless vector control, equipped with many additional functions, that can be used in many difficult applications.

![]() 1-phase and 3-phase power supply 3x230V and 3x400V

1-phase and 3-phase power supply 3x230V and 3x400V

![]() Rated power from 0.4kW to 22kW

Rated power from 0.4kW to 22kW

![]() option of an external keyboard

option of an external keyboard

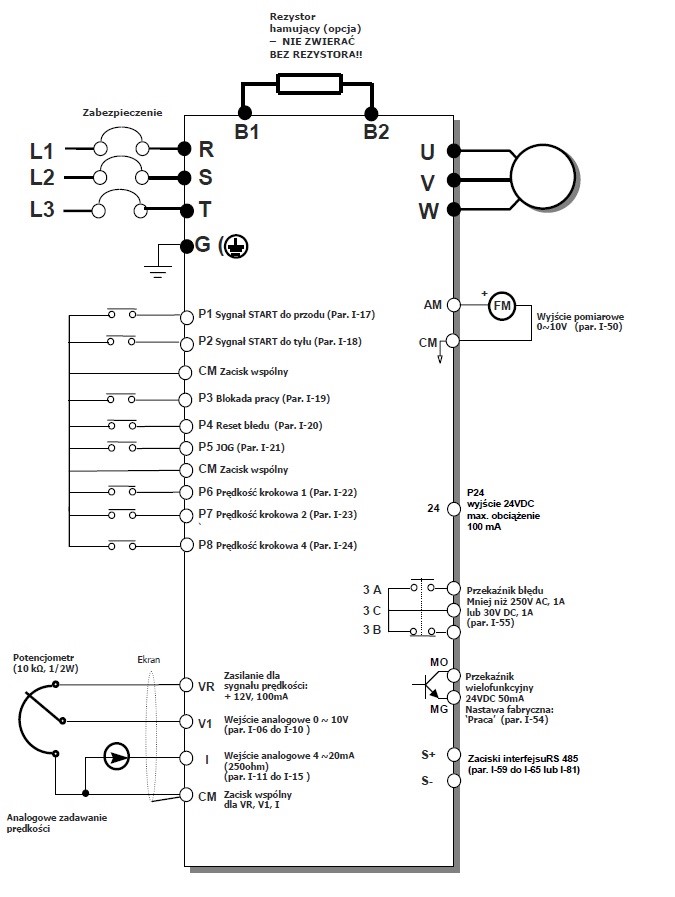

![]() built-in braking module and Modbus communication

built-in braking module and Modbus communication

![]() analog input -10 .. + 10V / 0-10V and 4-20mA

analog input -10 .. + 10V / 0-10V and 4-20mA

![]() the ability to control the signal -10 … + 10V

the ability to control the signal -10 … + 10V

![]() many ways to control the speed of the engine

many ways to control the speed of the engine

More information about the iG5A series

Characteristic:

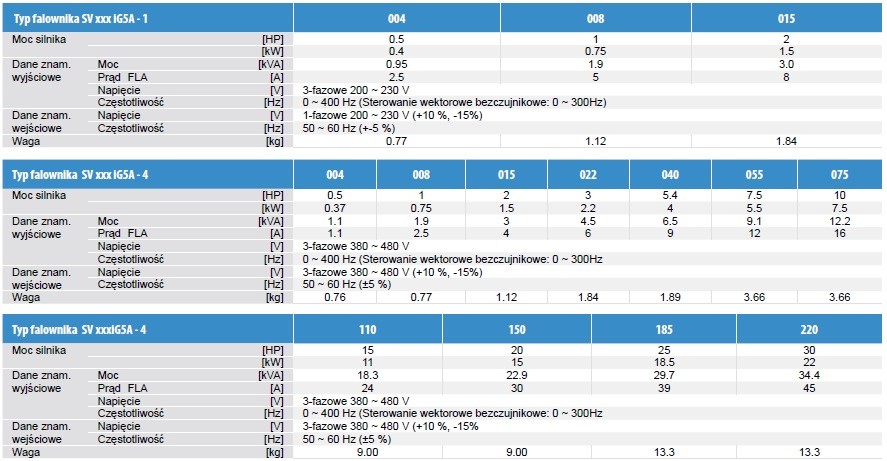

The iG5A series is available in two versions: with single-phase power supply and with three-phase power supply. It covers the engine power range from 0.4KW to 22KW. As standard, the inverter is equipped with a C4 category EMC filter, a braking module and an integrated user interface in the form of a control panel. The presence of many dedicated functions and a great value for money is an excellent value. The iG5A drive is an economical, reliable and flexible solution for most applications. As an option, there is an external keyboard with a cable that can be installed on the facade of cabinets or control cabinets. IG5A is largely reminiscent of the iC5 series in terms of distribution and number of parameters. The parameters are distributed in four transparent groups. For the basic operation it is enough to implement, as in the iC5 series, five basic parameters. Due to the presence of a built-in braking module, the drive is ideally suited where dynamic braking or short stopping time of the drive is required. This model is also available in a special version, with an output frequency up to 1000 Hz (CNC spindles).

Parameters and main functions:

The iG5A inverter has many dedicated application functions. The main advantage of the converter is its versatility, flexibility and general purpose. And so, due to the dedicated functions, it is possible to operate the engine brake, especially important in applications such as: elevators, lifts, overhead cranes. The built-in rewinder calculator allows you to build simple rewinding and winding systems. Simple to operate PID control gives the possibility to regulate many processes. Main product features:

![]() Available in single-phase (0.4-1,5KW) and three-phase (0.4KW – 22KW) power supplies.

Available in single-phase (0.4-1,5KW) and three-phase (0.4KW – 22KW) power supplies.

![]() V / f control algorithm and sensorless vector.

V / f control algorithm and sensorless vector.

![]() Motor autotuning function.

Motor autotuning function.

![]() High start torque.

High start torque.

![]() Brake function.

Brake function.

![]() The rewinder calculator function.

The rewinder calculator function.

![]() Built-in braking module and EMC C4 filter.

Built-in braking module and EMC C4 filter.

![]() PID controller for process control.

PID controller for process control.

![]() Freely programmable inputs / outputs (up to 8 digital inputs).

Freely programmable inputs / outputs (up to 8 digital inputs).

![]() Controlling inputs in the NPN and PNP standards.

Controlling inputs in the NPN and PNP standards.

![]() Built-in full engine security package.

Built-in full engine security package.

![]() The speed search function.

The speed search function.

![]() KEB (kinetic energy buffering) function.

KEB (kinetic energy buffering) function.

![]() Automatic work.

Automatic work.

![]() Up / down and motopotentiometer control.

Up / down and motopotentiometer control.

![]() Forcing manual and automatic torque.

Forcing manual and automatic torque.

![]() Built-in Modbus RTU communication.

Built-in Modbus RTU communication.

![]() Available, optional control keyboard (removable).

Available, optional control keyboard (removable).

Models & specs:

Terminal strip connections- view:

Purpose:

The iG5A series inverter has a universal purpose and can be used in many applications: pumps and fans,conveyors, mills and mixers, crushers, centrifuges, presses, spindles, overhead cranes, and many more. The iG5A series is the most economical drive solution with wide application possibilities.