Robotization of industrial processes

Robotization of industrial processes

In the era of Industry 4.0, the use of robots in manufacturing companies is no longer fancy additive, but very often a necessity. Properly selected and configured production robots increase productivity, ensure competitiveness and continuity of processes. In cooperation with a human being or alone, they are able to perform almost any given task. The investment that is a robot quickly brings benefits and guarantees the company’s development.

The most important features of robots are:

![]() Availability to work 24/7 (especially important in companies where the production process is continuous or there is a shortage of employees)

Availability to work 24/7 (especially important in companies where the production process is continuous or there is a shortage of employees)

![]() low error rate, improving the quality of products (the robot repeats almost exactly the same operations in each cycle, doesn’t get „tired”)

low error rate, improving the quality of products (the robot repeats almost exactly the same operations in each cycle, doesn’t get „tired”)

![]() relieves man’s work, improves safety by carrying out tasks type dangerous for people (i.e. in the process of product palletizing)

relieves man’s work, improves safety by carrying out tasks type dangerous for people (i.e. in the process of product palletizing)

![]() versatility – one robot can perform several different tasks, and uploading new software allows you to change the use of the robot almost immediately.

versatility – one robot can perform several different tasks, and uploading new software allows you to change the use of the robot almost immediately.

ANIRO offers solutions using KUKA, Kawasaki, Universal Robots and Epson robots.

ROBOT IMPLEMENTATION PROCESS

PALLETIZING

Internal product transport and logistics are one of the most important challenges of modern production. Palletizing and depalletizing performed by man absorbs a lot of energy and time. A much more effective solution is the use of robots and the automation of processes in which man will perform just a supervisory function.

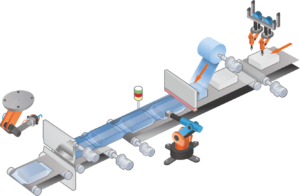

ROBOTIZATION OF PRODUCTION PROCESSES

Robots can participate in almost any task in the production process in which machines are used, like quality, pick & place, internal transport or quality control is performed. Properly adapted robots will cooperate with CNC machines, paint product elements, sort or select defective elements on the production line. The robot successfully replaces a man in harmful conditions, dangerous to health or in an environment with increased temperature onerous for employees.

OUR PARTNERS